How to Choose the Best Snow Retention System

The following is a portion of an article that was originally published in the Metal Construction News.

Snow Retention: Compatible Solutions for the Life of the Roof!

When choosing snow retention systems today, one can be inundated with rhetoric from dozens of suppliers all touting that theirs is the best, the first, the newest, the oldest, the only…and it goes on. What is really important when selecting a snow retention product for a state-of-the art roof system? How does a contractor, building owner, or designer sift through all the vendor claims to get past the rhetoric and ferret out important aspects of snow retention systems?

1. The snow retention system should do the roof no harm.

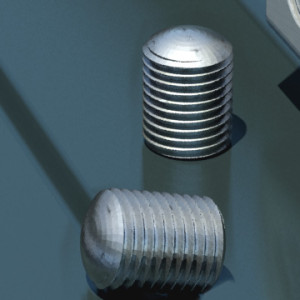

The attachment should be carefully scrutinized with respect to preservation of rooftop warranties. Devices that are mechanically attached should use fastening methods that do not penetrate the weathering membrane of the roof. Further, the fastening should not break the protective metallic coatings of steel panels or cause scoring which can lead to roof material fracture, or premature corrosion, violating material warranties. Typical “cup point” set screws dig through the fragile protective metal coatings of carbon steel panels, exposing the bare metal to corrosion. Round point setscrews preserve these coatings, leaving warranties intact.

The attachment should be carefully scrutinized with respect to preservation of rooftop warranties. Devices that are mechanically attached should use fastening methods that do not penetrate the weathering membrane of the roof. Further, the fastening should not break the protective metallic coatings of steel panels or cause scoring which can lead to roof material fracture, or premature corrosion, violating material warranties. Typical “cup point” set screws dig through the fragile protective metal coatings of carbon steel panels, exposing the bare metal to corrosion. Round point setscrews preserve these coatings, leaving warranties intact.2. The system should be compatible with the expected life of the roof.

Galvalume®-coated steel has demonstrated performance life expectancy of 40 years or longer in most environments. Aluminum can be expected to render an even longer service life. Copper, zinc and terne go up from there. The snow retention system should meet the same criteria. Many devices being marketed today are either corrosive metals, or plastic, having nowhere near this kind of expected service life, hence replacement of such devices must be expected several times before the roof life has expired. Many devices rely on dyes or air-dried paint to color match to architectural roofs. While the color match is perfect at the onset, the match is temporary. Over time, the inferior pigments and resins of the snow guard fade quickly; producing a very unsightly mismatch to the more stable PVDF factory finishes of the roof panels. Finally, the method of attachment must also last the life of the roof. Mechanical attachments do not change with time. Chemical attachments (adhesives) weaken with age and exposure as UV, moisture and thermal cycling break down the chemical bonds. This is a fact of chemistry that cannot be ignored.

Galvalume®-coated steel has demonstrated performance life expectancy of 40 years or longer in most environments. Aluminum can be expected to render an even longer service life. Copper, zinc and terne go up from there. The snow retention system should meet the same criteria. Many devices being marketed today are either corrosive metals, or plastic, having nowhere near this kind of expected service life, hence replacement of such devices must be expected several times before the roof life has expired. Many devices rely on dyes or air-dried paint to color match to architectural roofs. While the color match is perfect at the onset, the match is temporary. Over time, the inferior pigments and resins of the snow guard fade quickly; producing a very unsightly mismatch to the more stable PVDF factory finishes of the roof panels. Finally, the method of attachment must also last the life of the roof. Mechanical attachments do not change with time. Chemical attachments (adhesives) weaken with age and exposure as UV, moisture and thermal cycling break down the chemical bonds. This is a fact of chemistry that cannot be ignored.3. The system should not detract architecturally from the curb appeal of the roof.

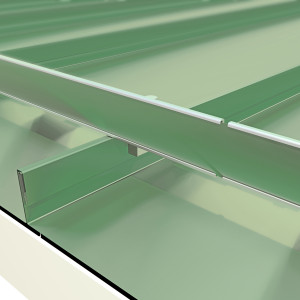

Clean lines and material finishes that are the same as the roof material itself will compliment a long life roof system with lasting quality and aesthetic appeal. The aging effects of the device should also be considered from an aesthetic standpoint: The way they look when new may be quite different than in an aged condition. Organic materials like plastics are marketed as being “invisible”, but these compounds are chemically altered with age, producing oxidation and other discoloration effects that can be quite unsightly after six or eight years of exposure. Of course beauty is in the eye of the beholder so the aesthetic style of any device should be suited to the user or designer.

Clean lines and material finishes that are the same as the roof material itself will compliment a long life roof system with lasting quality and aesthetic appeal. The aging effects of the device should also be considered from an aesthetic standpoint: The way they look when new may be quite different than in an aged condition. Organic materials like plastics are marketed as being “invisible”, but these compounds are chemically altered with age, producing oxidation and other discoloration effects that can be quite unsightly after six or eight years of exposure. Of course beauty is in the eye of the beholder so the aesthetic style of any device should be suited to the user or designer.4. The device should be appropriately and adequately tested for holding strength.

The number of untested or inappropriately tested products marketed today is alarming. Snow presents a calculable force on any rooftop and any snow guard device. The holding strength of any device is vitally relevant and should be verified by an independent laboratory in order to permit properly engineered installations. If an attachment method weakens as it ages, testing in an aged condition may be much more appropriate. MCA (Metal Construction Association) recommends factors of safety of three to five adhesive attachments, and two to three for mechanical ones. Many products advertise tensile strength or breaking strength of the part, rather than holding strength. Driving a truck over a part to prove it doesn’t break is a meaningless dramatization and such promotions are deceptive and irrelevant to in-service behavior. The real holding strengths vary widely and we have seen test results from various products that range from only 60 lbs. to over 4,000!

5. The system should be engineered to the specifics of the job.

When reliable holding strength of the device is known through appropriate laboratory testing, that strength (with appropriate factors of safety) can be matched to the specifics of the project by some simple math to determine placement frequency for the device. MCA’s recent publication on roof design for cold climates explains this design process. This should be done on a job-specific basis to produce a system that is custom tailored to the in-service requirements of each project. This important step assures that the system can withstand the forces that will try to tear it from the roof; in short, to be sure the system will not fail in service under design loads. When this is done, the unit price that appeared to be the lowest cost is often the highest.

When reliable holding strength of the device is known through appropriate laboratory testing, that strength (with appropriate factors of safety) can be matched to the specifics of the project by some simple math to determine placement frequency for the device. MCA’s recent publication on roof design for cold climates explains this design process. This should be done on a job-specific basis to produce a system that is custom tailored to the in-service requirements of each project. This important step assures that the system can withstand the forces that will try to tear it from the roof; in short, to be sure the system will not fail in service under design loads. When this is done, the unit price that appeared to be the lowest cost is often the highest.6. The system should be easy to install.

Things in the field are less perfect than things in a lab. Products that require special preparation, expensive primers, critical sealant applications and adhesive cure times at laboratory conditions for as long as 180 days to achieve published holding strength are not reasonable expectations on a job site, and will rarely be done as instructed. Installation error can jeopardize even the best system.

7. The system must be cost effective.

Of course cost is always an important factor and the lowest cost solution meeting the above criteria will win out over the rhetoric. It is important to compare total installed system cost of each alternative on a project-specific basis. To do so sometimes produces surprising results. Better is often less expensive!

Do you want to find out more about how S-5!® Snow Retention Systems excel? Check out the page for A.B. Martin’s in-stock snow guards.