S-5! Clamps

AB Martin is a top-tier distributor of S-5! Clamps and one of the few stocking distributors in the country. That means your orders are ready to ship without delay and at some of the best prices available. Who doesn’t like to save time and costs? Order today.

Contact us to speak to one of our knowledgeable sales representatives, or view our online S-5! Clamps product catalog.

S-5! roof clamps attach to the panel seam by the tightening of two “bullet-nosed” stainless steel setscrews against the seam material. (This is usually done with an industrial grade screw gun.) The setscrews compress the seam material against the opposite wall of the clamp. They will “dimple” the seam material, but will not penetrate it. Threaded holes in the clamp (and stainless hardware provided) enable the easy attachment of various ancillary items to the clamps.

S-5! Clamps

S-5-PV Kit

The new S-5-PV Kit is one of the first solar module-mounting solutions in the industry to be listed in the new UL subject 2703, a standard that covers both bonding and mounting.

In most cases, the savings in time and materials is sufficient to pay for the entire S-5-PV Kit and clamp setup! The S-5-PV Kit continues to be the easiest, most cost-effective way to install solar panels directly to standing seam metal roofs and remains the most popular choice worldwide.

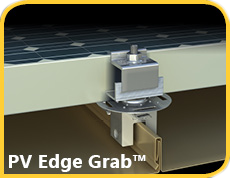

EdgeGrab™

S-5!’s new EdgeGrab™ is specifically designed to be used in conjunction with our patented S-5-PV Kit for solar array end conditions.

EdgeGrab uses the same S-5-PV Kit base assembly as the universal PV grab and will work on most exposed-fastened and corrugated metal roofs.

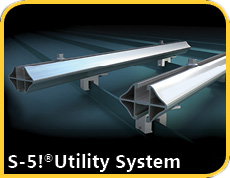

S-5!® Utility System

The new S-5!® Utility System is the most versatile utility mounting solution for standing seam metal roofs, and is exclusively by S-5!

The Utility System enables easy attachment of almost any conceivable utility application, including; signs, banners, light fixtures, gas piping, antennas, roof walkways, HVAC equipment, cabling, and more.

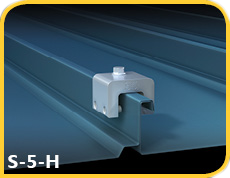

S-5-H

Specifically developed to securely and cost-effectively accommodate metal roof panels with a horizontal seam. It is unique in that it allows for attachment to a horizontal seam on the vertical leg of the seam.

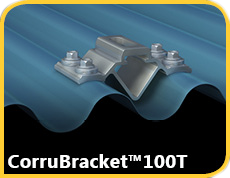

CorruBracket™100T

Designed specifically for corrugated roofing profiles that are common in North America. It is affixed to the crest of the corrugation, leaving the drainage plane free of holes to protect against leaks.

Having no messy sealants to apply, CorruBracket 100T comes with a factory-applied EPDM rubber gasket seal already on the base, and the S-5!®-patented reservoir conceals the EPDM from UV exposure, preventing UV degradation.

RibBrackets™

Used to mount almost anything onto the most common exposed-fastened, trapezoidal roof profiles marketed in North America today. No messy sealants to apply! No chance for leaks! It comes with a factory-applied EPDM rubber gasket seal already on the base, and the S-5!® patented reservoir conceals the EPDM from UV exposure, preventing drying and cracks.

VersaGard™

Compatible with almost any trapezoidal, exposed-fastened profile. No messy sealants to apply! No chance for leaks! VersaGard comes with factory-applied butyl sealant already in the base, and the S-5!®-patented reservoir conceals the sealant from UV exposure, preventing drying and cracks.

S-5-V

A versatile clamp that fits vertical-folded seam profiles manufactured in North America.

Installation is as simple as setting the patented round-point setscrews into the clamp, placing the clamp on the seam, and tightening them to the specified tension. Then, affix ancillary items using the stainless steel bolt provided with the product.

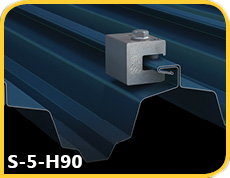

S-5-H90

A one-piece clamp that was developed to securely and cost-effectively accommodate metal roof panels with a horizontal seam greater than 0.65″.

Turning the clamp 90 degrees so that the bolt hole side is facing up, slip the clamp on the seam and tighten the setscrews.

S-5-N1.5

Designed with patented S-5!® zero-penetration technology for application on the popular 1.5″ nail strip metal roof profiles and roofing types with similar profiles. (Please note these clamps were not designed to fit all nail strip profiles.) The clamp boasts an angular throat that accommodates most nail strip profiles, minimizing the need to field crimp. An angled wall with a nose permits the S-5-N 1.5 to engage the triangle type profiles during the installation process—there is no longer a need to hold the clamp in place while setscrews are tensioned. The combination of these two features allows the clamp to sit straighter on the seam.

S-5-U

By far our most popular and most versatile clamp. It will fit about 85% of the standing seam profiles manufactured in North America. It can be used on vertically oriented seams, and by rotating the clamp 90 degrees, it can also be used on most horizontal 2” seam profiles. Its simple design, generous dimensioning and multiple hole orientations are what make it so versatile for use with S-5!® snow retention products and other heavy-duty applications.

S-5-E

Designed especially for double-folded standing seam roof profiles having the appropriate dimensioning. This clamp is also the one recommended for Butler’s MR24™.

Although a bit smaller and less expensive than the S-5-U, for these profiles, the S-5-E is just as strong.

S-5-S

Extraordinarily versatile clamps, specifically designed for popular snap-together standing seam profiles. The S-5-S or S-5-S Mini can be used to avoid having to crimp-seam profiles such as Firestone UC4 and New Tech Machinery SS550 and SS675. They also accommodate horizontal seams where the horizontal projection is under 0.54 inches without the need to double fold the seam!

S-5-N

For application on the popular 1″ nail strip metal roof profiles: Taylor Metals’ Easy Lock™, ASC Building Products’ Skyline Roofing®, McElroy Metals’ Meridian, and New Tech Machinery’s FF100, and roofing types with similar profiles. The clamp boasts a wider throat that accommodates most profiles, minimizing the need to field crimp. An angled wall with a nose allows the S-5-N to engage the triangle type profiles during the installation process—there is no longer a need to hold the clamp in place while setscrews are tensioned. The combination of these two features allows the clamp to sit straighter on the seam.